Description

For more difficult applications, CDS Manufacturing’s linear vibratory parts feeders offer easy access for adjustments and maintenance with first in first out product flow to help maintain the quality of your product. The open design of our linear vibratory parts feeder systems also allows for expandability and the addition of down line tools for secondary operations such as inspection, sorting, packaging, counting, insertion, assembly, and more…

For more difficult applications, CDS Manufacturing’s linear vibratory parts feeders offer easy access for adjustments and maintenance with first in first out product flow to help maintain the quality of your product. The open design of our linear vibratory parts feeder systems also allows for expandability and the addition of down line tools for secondary operations such as inspection, sorting, packaging, counting, insertion, assembly, and more…

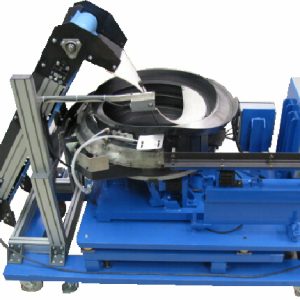

The bulk hopper provides parts to the recycler tray. The level of parts in the recycler tray is automatically maintained. Parts are fed to the custom orientation tooling on the orientation track. Parts in the wrong orientation are diverted back into the recycler tray. Parts in the proper orientation are fed out the end of the orientation track. CDS Manufacturing’s linear vibratory parts feeders are available in table top models, machine base mounted systems, miniature part feeder configurations, single and dual stage part recycler models, and can be equipped with pick and place and robot installation tooling.

The bulk hopper provides parts to the recycler tray. The level of parts in the recycler tray is automatically maintained. Parts are fed to the custom orientation tooling on the orientation track. Parts in the wrong orientation are diverted back into the recycler tray. Parts in the proper orientation are fed out the end of the orientation track. CDS Manufacturing’s linear vibratory parts feeders are available in table top models, machine base mounted systems, miniature part feeder configurations, single and dual stage part recycler models, and can be equipped with pick and place and robot installation tooling.

Check out this video of some past applications:

CDS Manufacturing has designed and built linear vibratory parts feeders for the following applications: light bulb filament feeders, magnet feeders, powdered metal parts feeders, pin feeders, eye glass stem feeders, pharmaceutical feeders, ‘S’ hook feeders, dome switch feeders, seat belt bracket feeders, clip feeders, sleeve feeders, brass fittings feeders, ceramic fuse body feeders, o-ring feeders, plastic parts feeders, motor housing feeders, spring feeders, cup feeders, lid feeders, plastic parts feeders, handle feeders, blade feeders, bushing feeders, mascara brush feeders, and more…

For simpler applications, check out our Vibratory Bowl Feeder Systems.

Contact Us today for more information about our linear vibratory parts feeders.